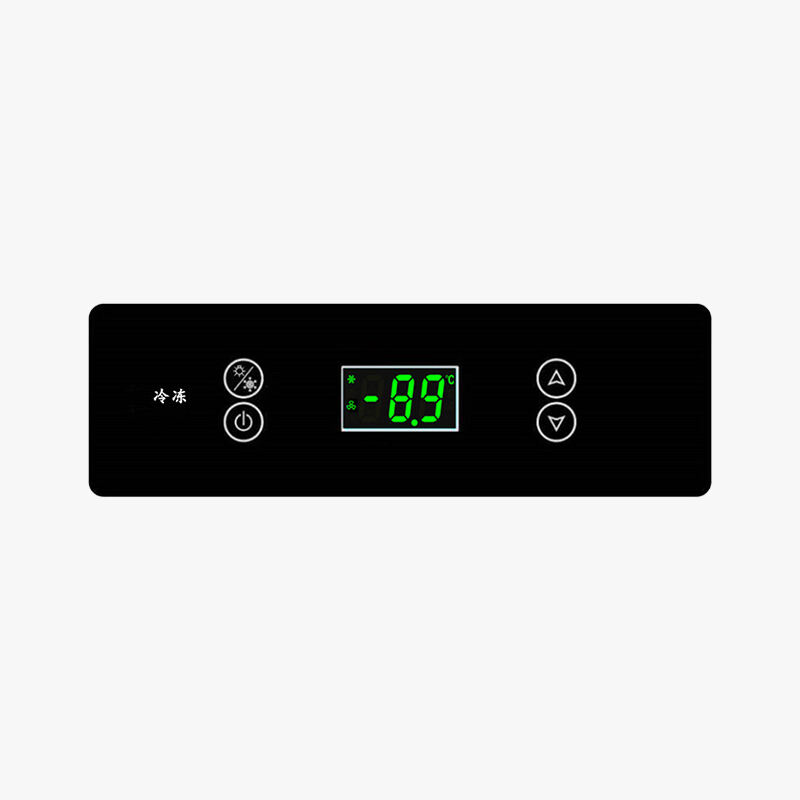

Advanced Control Algorithm Precision

The sophisticated PID algorithm at the core of these temperature controllers represents a significant technological advancement in thermal management. This intelligent system continuously calculates and adjusts three crucial parameters: proportional band, integral time, and derivative time. The proportional component provides immediate response to temperature deviations, while the integral function eliminates steady-state errors. The derivative action anticipates future changes based on the rate of temperature variation, resulting in exceptionally stable control. This advanced algorithm ensures temperature accuracy within ±0.1°C, making it ideal for critical applications where precise temperature control is essential. The system's ability to adapt to changing conditions and maintain stability under various load conditions sets it apart from simpler control methods.