Advanced Quality Control Systems

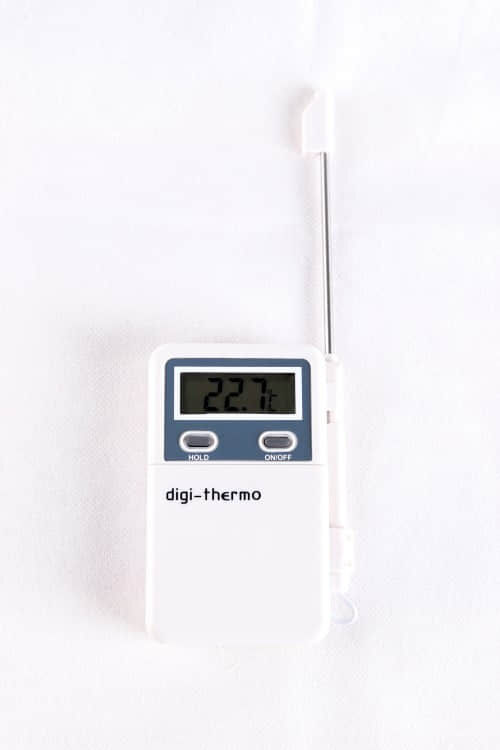

The factory's quality control system represents the pinnacle of manufacturing excellence, incorporating multiple layers of inspection and testing processes. Each temperature control unit undergoes comprehensive testing at various stages of production, utilizing automated testing equipment that can detect even minor deviations from specifications. The system employs artificial intelligence and machine learning algorithms to predict potential quality issues before they occur, enabling preemptive corrections in the manufacturing process. The facility maintains climate-controlled testing environments that simulate various operating conditions, ensuring components perform reliably across different scenarios. Statistical process control methods are implemented to monitor and maintain consistent product quality, while detailed documentation and traceability systems track each component throughout the production process.