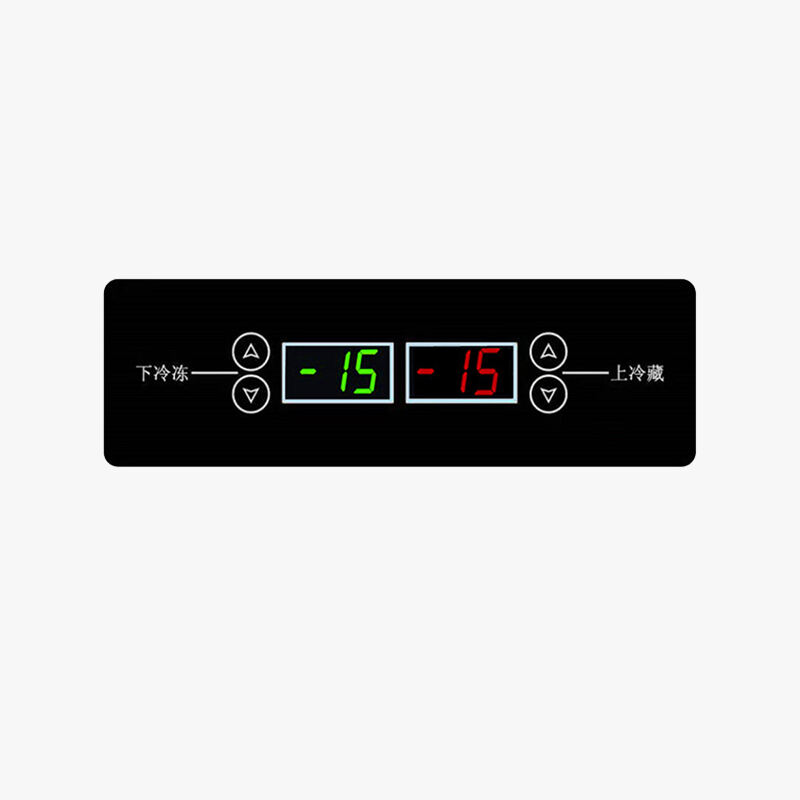

Precision Temperature Control with Advanced Timing Functions

The digital temperature controller's sophisticated temperature management system combines high-precision control with versatile timing capabilities, setting new standards for process automation. The controller maintains temperature accuracy to within ±0.1°C, utilizing advanced PID algorithms that continuously adjust output parameters based on real-time feedback. This precision is coupled with comprehensive timing functions that allow users to program complex temperature profiles with multiple stages and durations. The system can handle both simple timed operations and elaborate multi-step processes, making it suitable for applications ranging from basic heating and cooling cycles to complex thermal processing sequences. The controller's adaptive tuning capabilities automatically optimize control parameters based on system response, ensuring optimal performance across different operating conditions and load changes.