Advanced Technology Integration

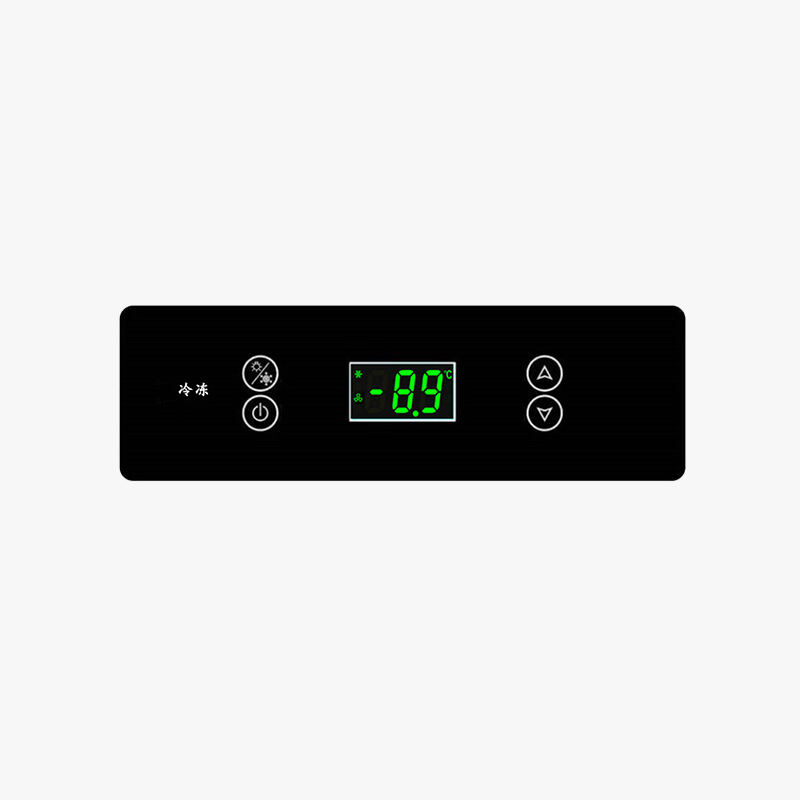

Digital temperature controller manufacturers excel in incorporating cutting-edge technology into their products. Their controllers feature sophisticated microprocessors that enable complex control algorithms, ensuring precise temperature regulation across various applications. These manufacturers implement advanced PID control systems with auto-tuning capabilities, allowing the controllers to automatically optimize their performance based on specific application requirements. The integration of modern communication protocols enables seamless connectivity with industry standard networks, facilitating remote monitoring and control capabilities. Many controllers include built-in data logging features with expandable memory options, allowing for comprehensive process monitoring and analysis. The manufacturers also focus on developing user-friendly interfaces with high-resolution displays and intuitive programming options, making complex temperature control operations accessible to operators of all skill levels.